|

|

The product VERGLIMIT is a chemical multicomponent de-icer which is added to the top course mix of bituminous surfacing. |

|

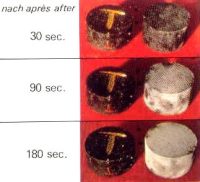

Laboratory freezing tests Two Marshall briquettes, one with and one without VERGLIMIT have been frozen to - 15°C and than stored in a moisture room. The photo shows that VERGLIMIT eliminates hoarfrost. |

specific gravity particle size melting point pH of solution apparent density shake density |

Technical properties 1.80 g/ml 0.1 - 5mm 175°C 11 - 12 0.84 g/ml 0.86 g/ml |

|

Placing Placing and compaction is done conventionally (repaving possible) Proper compaction is the most important criterion. The air- voids of the compacted pavement should be targeted at between 3 - 4 %. First roller must be used dry. |

|

Marshall test is appropriate except for the 30 min. water storage. The air-voids are adjusted to 2 - 3 vol. %. The asphalt cement content is raised by ( 0.3 to 0.5 ) % by weight. |

|

Gritting / washing to improve the skid - resistance properties of the new surface, crushed sand or screenings (0.1-3mm; ca 1kg / m2) slightly pre - coated should be rolled into the hot surface (min. 90°C) Immediately after placement, VERGLIMIT at the surface, should be washed off with a large surplus of water |

|

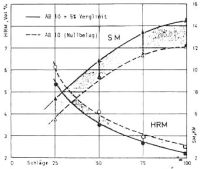

Stability air-voids and stability tests (AB 10) have shown, that the air-voids of the mix containing VERGLIMIT are a little lower while the stability is a little higher. |

|

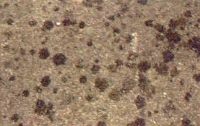

After placing Once the surface is worn in it needs no extra treatment afterwards. The dark spots are typical VERGLIMIT-spots. |

| IMPRESSUM © VERGLIMIT SA 2006 hosted by Trendpack SarlLast update: 2021.12.19 |